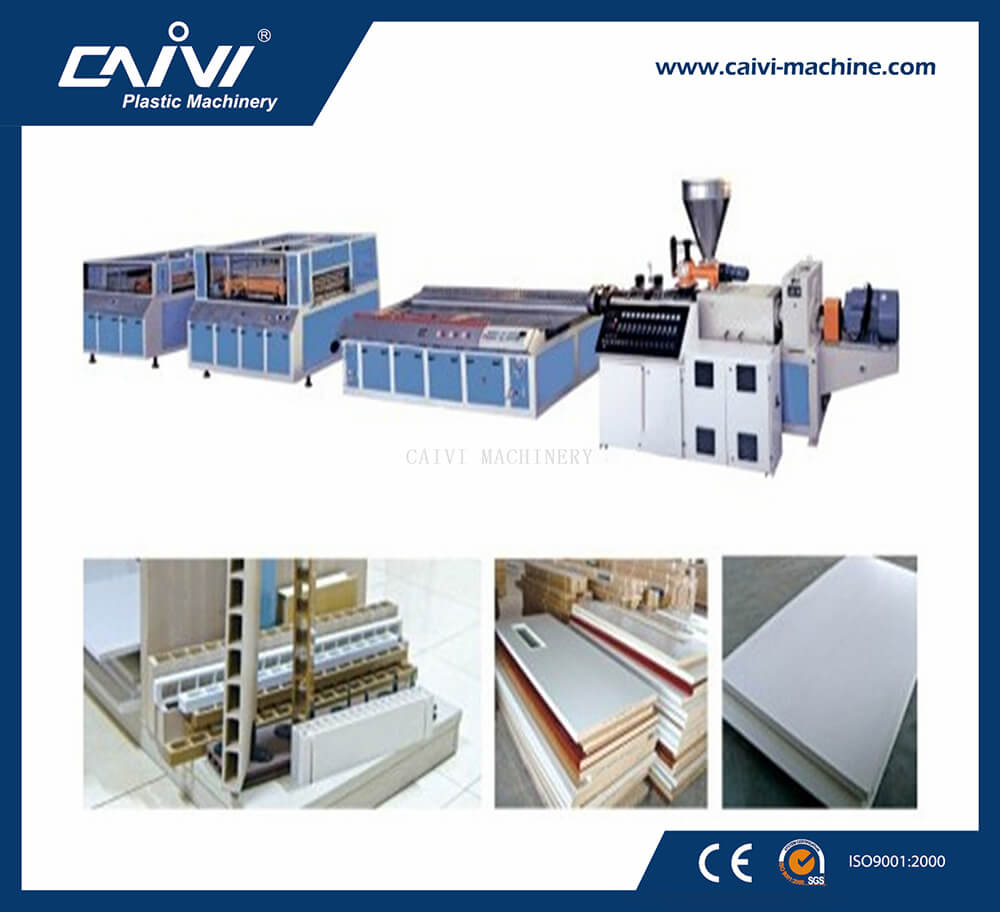

This line is used for production PVC decoration material with different shape and size for different application (Including PVC plastic doors and windows profiles, decorative plates, tiny foaming profiles and decorative plates, etc)

Feature of PVC Window Board Production Line

The unit adopts special-designed SJZ65 or SJZ80 conical twin screw extruder,adopts high quality frequency conversion for speed regulation.

It adopts famous temperature controller.It has advantages of wide adjustment range,high precision,convenient operation and so on.

The auxiliary machine is composite of vacuum calibration device,haul-off,cutter and turn-over stacker.This machine group adopts large cooling device to ensure the shaping result of plate.

The caterpillar drawing machine adopts high quality reducer,motor and frequency conversion.It has reasonable structure,large drawing force,steady drawing and so on.

The cutter has advantages of reliable and exact work,high precision of cutting and so on.

The turn-over stacker has mobile lorry and special rubber protection layer.It has advantages of no-wearing,simple use and so on.

The auxiliary machine adopts programmable controller or electric control system.The control of the whole machine is reliable and steady.

Technical Details of PVC Window Board Production Line

| Item Specification | YF610 | YF710 | YF810 |

| Max. Width of board(mm) | 610 | 710 | 810 |

| Extruder model | SJZ80/156 | SJZ80/156 | SJZ80/156 |

| Extruder power(kw) | 55 | 55 | 55 |

| Drawing force(KN) | 30 | 40 | 50 |

| Drawing speed (m/s) | 0.5-5 | 0.5-5 | 0.5-5 |

| Auxiliary equipment sum power(KW) | 31.6 | 31.6 | 31.6 |

| Compression air(Mpa) | 0.6 | 0.6 | 0.6 |