1.PVC Artificial Marble Profile Extrusion Line is mainly used for PVC Door& Window Profile, wide door plate, window plate making, the final product could be applied for decoration of house, hotel or other buildings.

2.The design of the final product is according to the design of the mold, clients could offer the product drawing and the mold same as the drawing could be designed and offered.

3.Rubber blocks in the Haul-off Machine will also be designed as the structure of the final product.

Feature of PVC Artificial Marble Production Line

1. Varied capacity: Capacity of main frame can be optionally chosen from 60-700 kg/h.

2. With twin conical screws extruder,it is particularly suitable for high speed extruding of profiled material.

3. The haul-off unit has applied unique lift technique of our co.Its work is stable,its reliability is good,its pulling force is large.

4. Vacuum setting has adopted special enlarged vortex cooling system which is good for cooling and calibrating so as to meet demand of high speed extruding.

5. Movement speed and drawing speed of cutting machine keep synchronous.

6. All movements are controlled by impacted PLC,the design is reasonable,the operation is stable,it can conduct automatic cutting with fixed length.

7. Powder & dust suction device can be provided.

8. With different molds,the tilter platform can choose such specifications.

Process Flow of PVC Artificial Marble Production Line

Raw material+additive→mixing → feeding → conical double screw extruder → co-extrusion screw extruder →Extrusion mould → cooling molding die → vacuum calibration tank → Hot stamping machine → haul-off → cutter → rack → finished product inspecting&packing

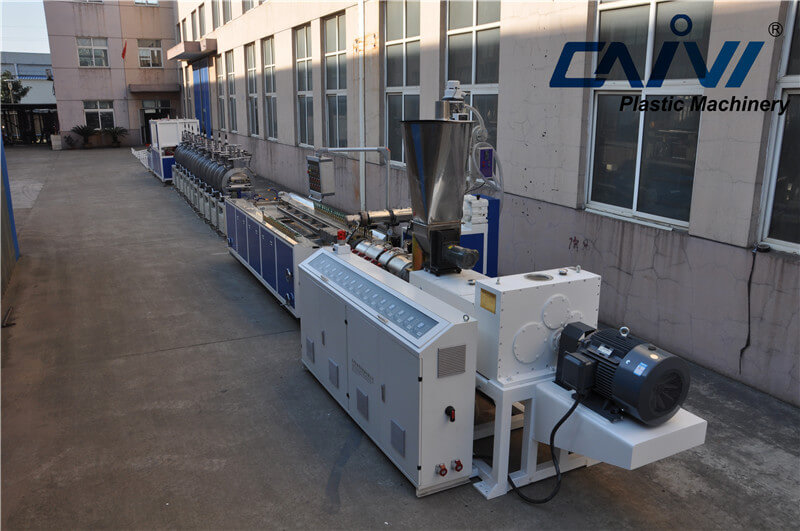

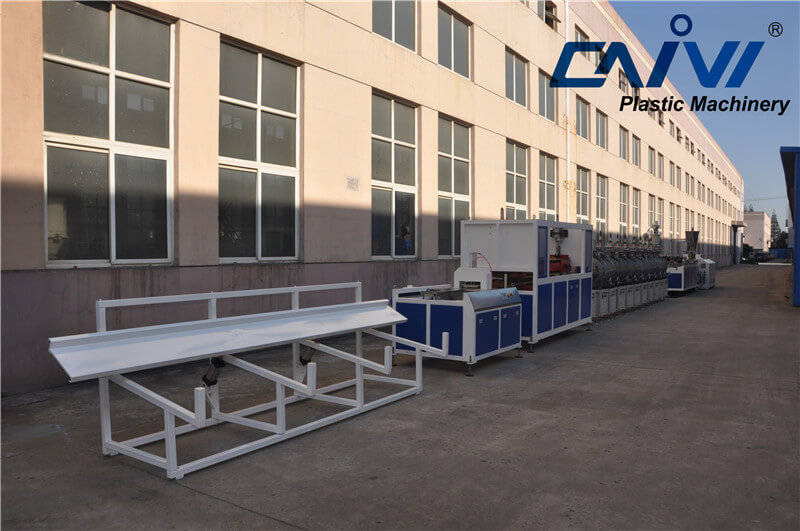

Photos of PVC Artificial Marble Production Line